Kam Oil

Exporting Oil Products To Global Markets

Continue increasing refinement capacity to further the goal of reducing – and ultimately eliminating – Afghanistan’s dependence on Energy imports.

Fueling Afghan Vehicles

Exporting Afghan Oil Products

Powering Afghan Jets

About Kam Oil

Kam International Oil was launched in 2013 as a joint venture between the Afghan-owned Kam Group and the Azerbaijani company AIFL. The initial $30 million dollar investment went towards the construction of Afghanistan’s first oil refining facility in Hairatan, along the Afghan-Uzbek border.

The refinery purchases crude oil extracted by the China National Petroleum Company (CNPC) at the Kashkari oil field in Afghanistan’s Sar-e-Pol province, which is then transported overland to Hairatan. At present 220 Afghan nationals are employed at Kam International Oil, with 30 Azerbaijani and other foreign nationals serving in positions that require oil refinement expertise. As the Afghan domestic oil-refin.

Products Information

MAZUT

Applications

NAPHTHA

Applications

DEISEL

Applications

BITUMEN

Applications

Consumer Markets

Consumer Markets

Consumer Markets

Consumer Markets

Strategic Vision

Increase oil product

Support Afghan energy

Build capacity in the Afghan Oil

Refined Oil

Based

Refinement Process

The Kam oil facility has the capacity to refine 500 metric tons of crude oil per day, with storage tankers available to store 25,000-28,000 tons of crude and processed oil. All refined products are then inspected by SGS, an international inspection and quality-control company. Sector matures, it is expected that more local staff will be qualified to fill senior technical positions within the company.

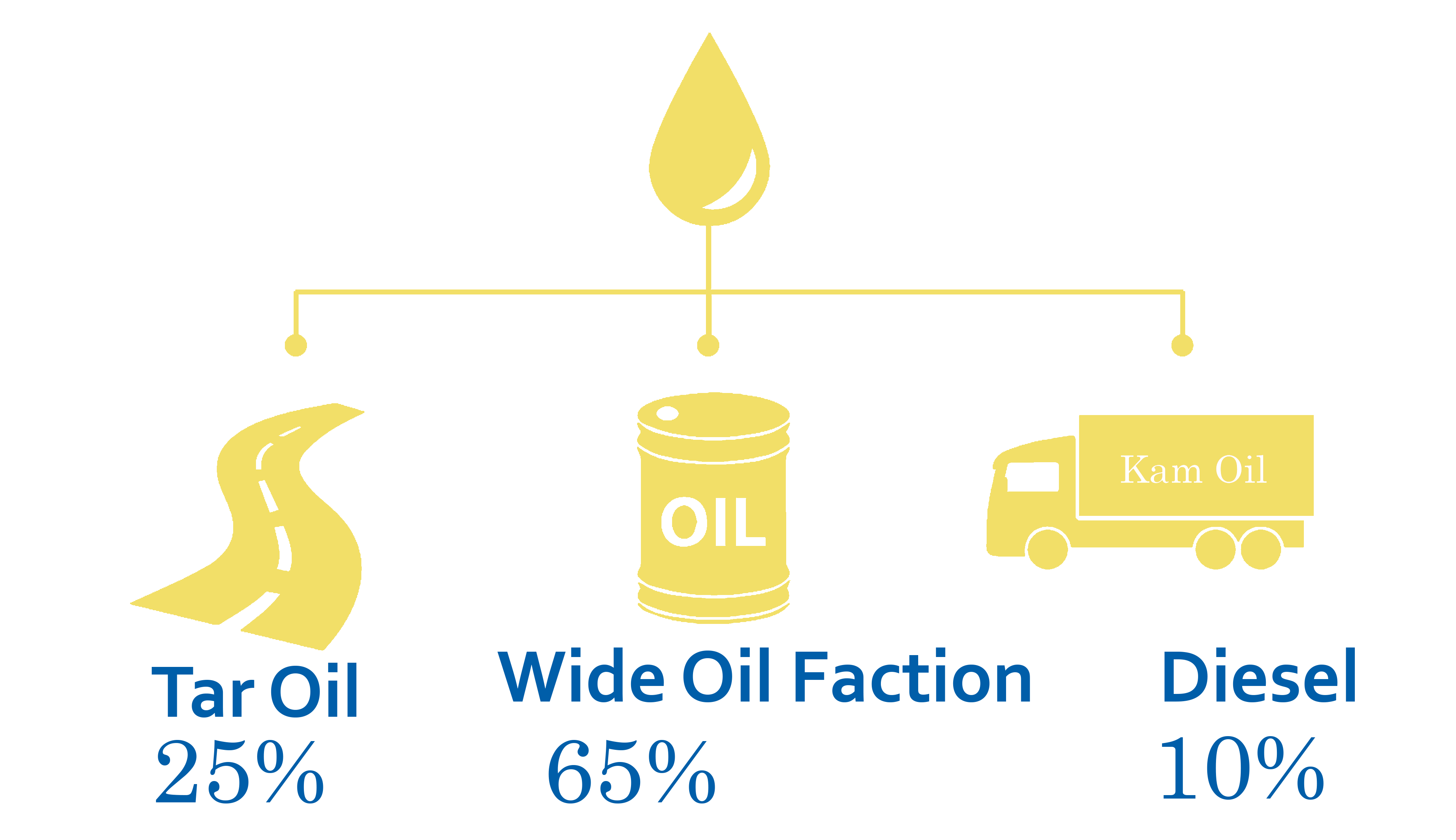

Stage 2:

Mazut (also referred to as “fuel oil” or “waste oil”) can be sold as is or undergo a second stage of processing. Mazut that undergoes a second round of processing results in the production of wide oil fraction (65% of output), diesel (10%) and tar oil (25%).

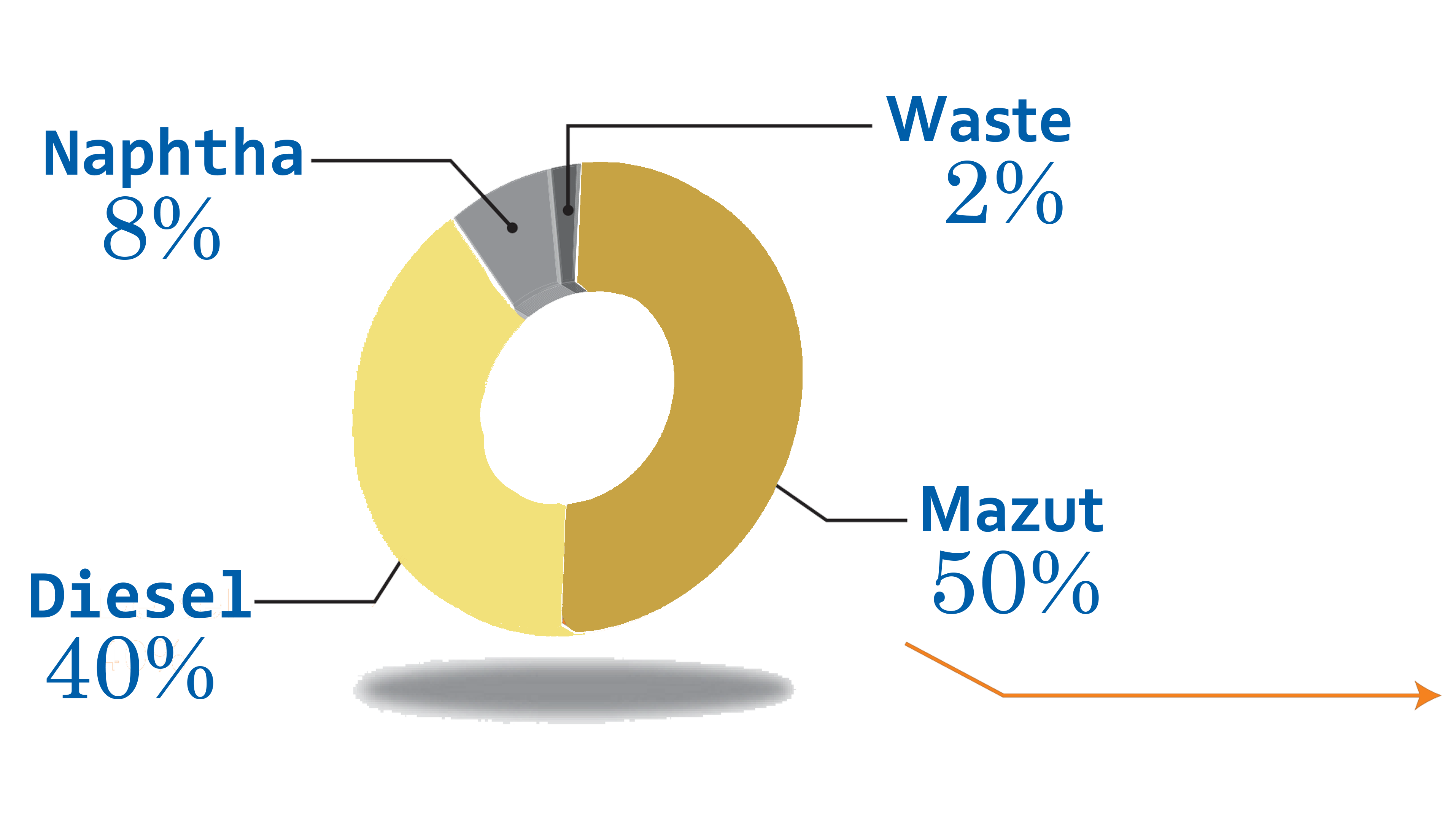

Stage 1:

The refining process takes place in two phases. The first

phase involves the conversion of the crude oil to mazut (50%

of the output), diesel (40%), and naphtha (8%). 2% of the

processed crude is discarded as industrial waste.

Want to Contact with us?